4solution

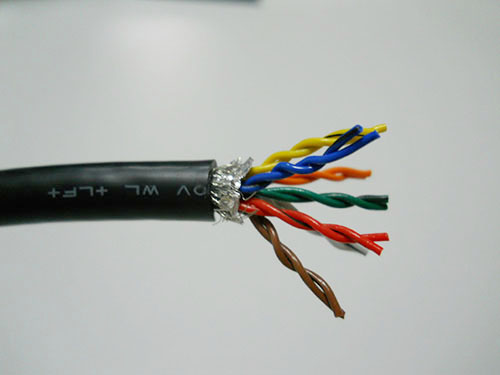

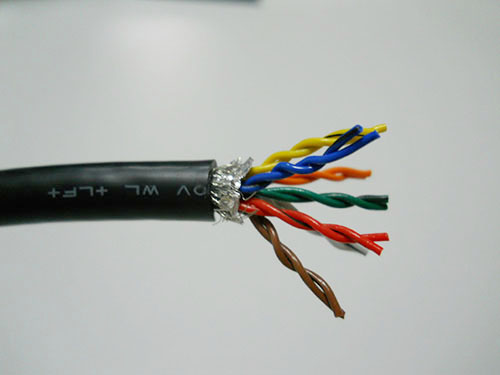

Towline cable as a category of wire and cable, widely used, excellent performance, are high-end cable, the process complex, demanding. With a high degree of flexibility, wear, folding, oil resistance, bending resistance, tensile, torsion, anti-interference, anti-aging and a series of unique features, towline cables are mostly used for industrial electronic systems, automatic generation line, storage equipment , Robots, servo motors, encoders, fire systems, cranes, CNC machines and metallurgical industries. In order to prevent cable entanglement, wear, pull, hanging and scattered, often the cable into the cable towline, the cable to form a protection, and the cable can also be moved back and forth with the towline. This cable in the laying of the time to pay attention to ways and means, a little careless, in the latter part of the time will cause a certain failure.

The first is that the laying of the towline cable can not be bent, because it is the cable protection in the inside, once bent or twisted serious, it will seriously damage the internal cable, resulting in equipment can not meet the needs of users. In the laying of the time, the cable should be spread out, and then according to the actual application of the standard laying of cables.

At this point must pay attention to the minimum bending radius of the cable. Long-term bending will cause the cable to deform.

Towline cable in use, must be loosely arranged in the towline, can not be all the cables are squeezed together, so as not to cause entanglement, it will also affect the use of cable

Both ends of the cable must be fixed or at least fixed at the moving end of the towline. The distance from the end of the cable should be 20-30 times the diameter of the cable.

Towline cable once fixed installation, do not arbitrarily forced to move, this will lead to the location of the cable deviation, affecting the practical application effect;

Make sure that the cable is fully moved within the bend radius so that the cables can move relative to each other or with the guide. After a period of operation, it is best to check the location of the cable. The check must be made after the push-pull movement.

In addition to the above points, users also need to pay attention to the application of towline cable, try to avoid the use of wet and high temperature places, otherwise it will lead to cable shell oxidation, shorten the service life.

nearly 20 years dedicated to providing quality wire and cable solutions

nearly 20 years dedicated to providing quality wire and cable solutions

nearly 20 years dedicated to providing quality wire and cable solutions

nearly 20 years dedicated to providing quality wire and cable solutions